Breaking down PECVD and Sputter Deposition

Summary: What is sputtering? What is PECVD? See what makes them so important in the film deposition process.

Summary: What is sputtering? What is PECVD? See what makes them so important in the film deposition process.

Breaking down the process of thin film deposition is quite simple. The process consists of various objects being coated by materials. This can be done with a single material or in multiple structures with layers.

The object that is being coated is known as the substrate. These can be anything from solar cells to optical components. With new vacuum deposition systems being introduced, the list continues to grow. The materials that coat the object can be atomic elements or molecules. This includes metals or non metals.

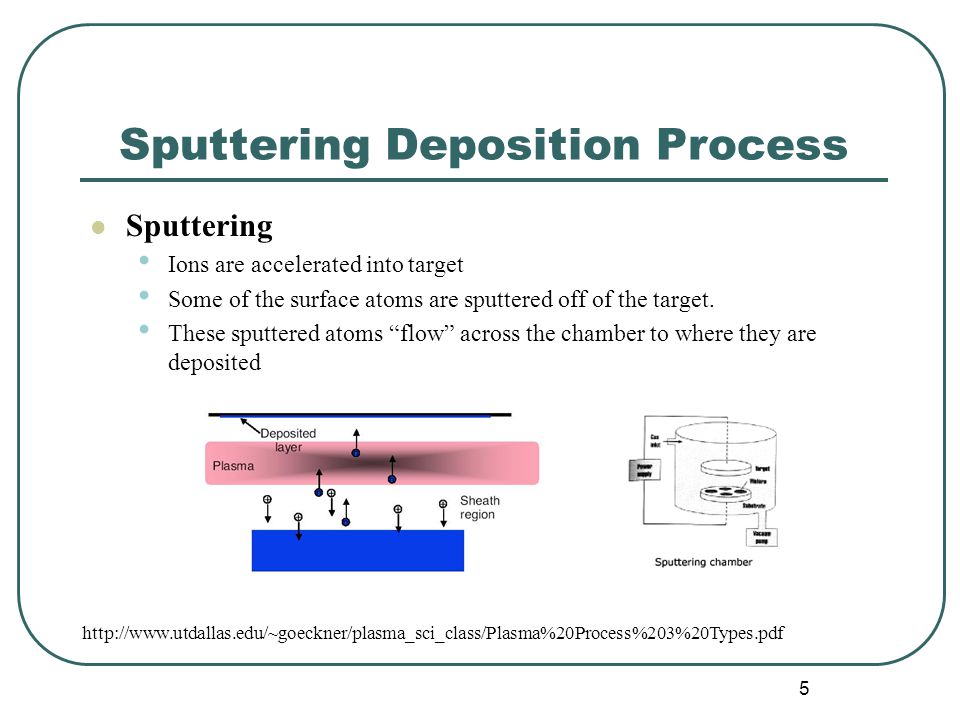

One method engineers use to coat substrates is called sputter deposition. What this does is it coats the substrate using plasma that sustains itself. The process goes through a phase where the cathode energizes itself, therefore creating the plasma and is then utilized for the coating.

An important variable that engineers have to look out for is good adhesion, without it, the substrate would likely fail to hold the film. This is why proper handling and cleanliness must be observed throughout the procedure.

On the other hand there is a method that can take a vapor and form it into a solid film, called plasma-enhanced chemical vapor deposition, or PECVD. This form is peculiar because unlike other methods that require a higher temperature to be able to coat substrates, this technique generates plasma through electrical energy with a lower temperature range. What you can expect out of PECVD substrates are a low density and good uniformity, making it an excellent choice as a film deposition option.